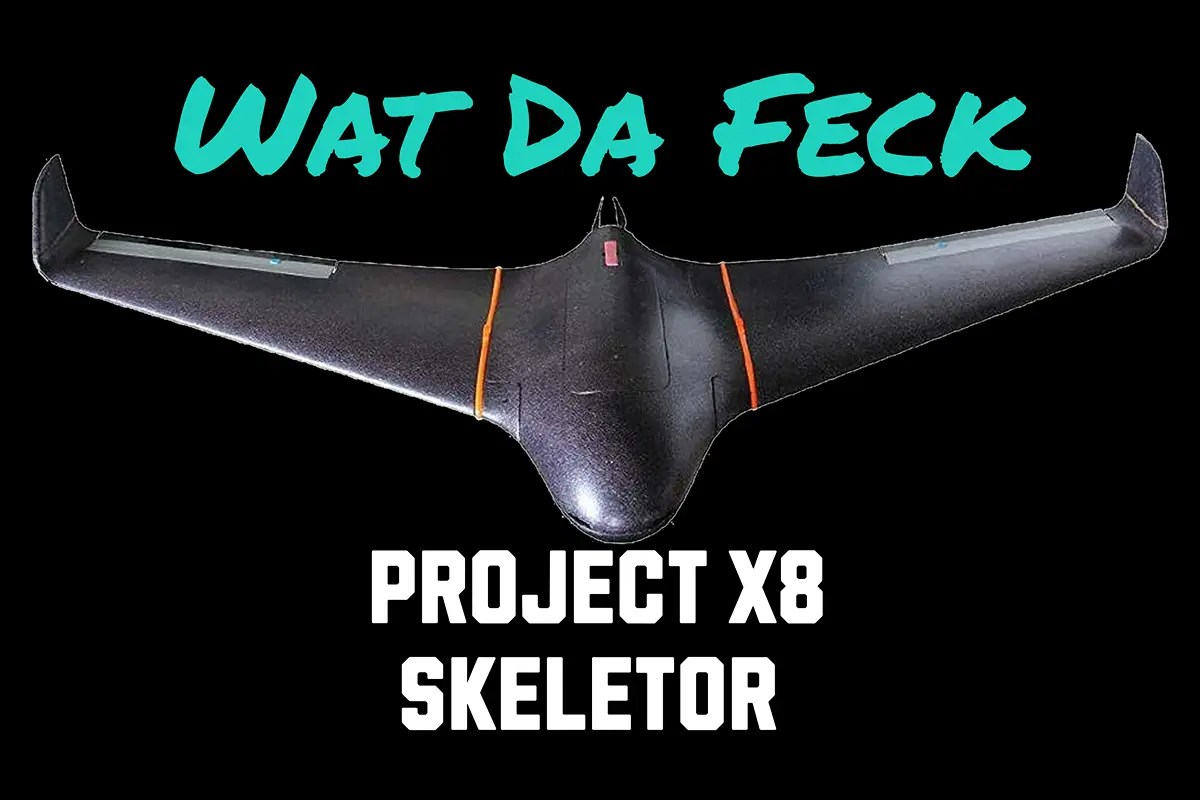

When it comes to wings, the Skywalker X8 is already a chunky flying Dorito. But once you start adding fiberglass cloth, polyurethane varnish, FPV gear, and dreams of long-range stability, the stock foam just doesn’t cut it anymore.

That’s why we made a series of upgrades to give the wings more rigidity, easier servicing, and smarter mounting solutions.

Carbon Fiber Reinforcement – Giving Foam Some Backbone

Foam wings are light and efficient, but they flex. And wing flex is about as reassuring as a bendy ladder.

Our solution:

- 2 × square carbon fiber rods (4 mm) installed — one toward the front spar area, and one toward the rear.

- These form a box-like reinforcement, drastically reducing torsional flex while keeping weight manageable.

Think of it as giving the X8 wings a rebar skeleton — same shape, just a lot less wobbly.

The 4 mm carbon spars needed to sit perfectly flush with the wing’s surface, which meant carving out a slot in the EPO foam. I went “old school” on this one: metal ruler as a guide, box knife in hand, and a slow, steady series of cuts. After scoring a 4 mm channel, I carefully picked the unwanted foam out until the spar sat neatly in place.

Looking back, I probably could have saved time by just grabbing the Dremel with a 4 mm router bit and guard — but hey, sometimes you’ve got time to kill and there’s something oddly satisfying about doing it by hand.

Once the slot was ready, the carbon tube was bedded in with expanding Gorilla Glue and left overnight to cure. Solid, simple, and just the right amount of messy.

Wire Ducting – Future-Proofing for Servo Replacements

Once the wings are laminated in fiberglass cloth + polyurethane, opening them up to replace wiring would be like asking to unbake a cake.

So we added a 10 mm carbon fiber tube running from the wing root to the servo location.

- This serves as a wire duct, making it easy to replace wires or even swap out a servo if needed.

- No more “hope the servo never fails” engineering.

Instead, we now have a future-proof maintenance tunnel built right into the wing.

3D Printed Custom Servo Mounts – Because Hot Glue Isn’t a Strategy

Stock foam cutouts and hot glue are fine… until you want to remove a servo. Then it becomes an archaeological dig.

We solved this with a 3D printed PETG mount system:

- Glue-in standoff block with an M3 brass insert melted in.

- Removable PETG carrier bracket that bolts into the insert.

- Servo slides in, bolts down, and can be replaced anytime.

This gives us:

- A rigid mount that won’t pull loose.

- Serviceability — no cutting foam to replace a dead servo.

- Engineering satisfaction (and fewer future swear words).

Servo Choice – The Numbers Game

The discussion of what servo to use came down to math. Specifically:

- Control surface size (elevon):

- 500 mm × 50 mm = 25,000 mm²

- Rule of thumb torque requirement:

- ~0.1 kg·cm per 1,000 mm² at cruise speeds

- Calculation:

- 25,000 ÷ 1,000 × 0.1 = 2.5 kg·cm minimum

- Safety margin (×2):

- 2.5 × 2 = 5 kg·cm required

So we needed at least a standard 15–20 g servo with ~6–12 kg·cm torque.

We tested options like:

- TD-8325MG (~25 kg·cm at 6V, 0.14s/60°)

- RDS3225 (~25 kg·cm, budget but proven)

Both more than meet requirements, with extra margin for gusts and aggressive maneuvers. plus to keep the cost down they was already surplus!

Wire Choice – Don’t Undersize the Lifeline

Servos don’t pull huge current, but voltage sag can kill performance.

- Typical current draw: 0.5–1 A average, up to 2–3 A in stalls.

- Two elevon servos = max ~6 A under abuse.

- Wire length = ~50 cm run per side.

We went with 22 AWG silicone wire:

- Handles up to 7 A comfortably.

- Flexible for routing through the 10 mm duct.

- Less voltage drop compared to 24/26 AWG.

This ensures no brown-outs when the servos actually need muscle.

The Payoff

By combining these upgrades, the X8 wings are now:

- Rigid (thanks to square carbon spars)

- Serviceable (10 mm duct + custom mounts)

- Reliable (servo torque matched to surface loads, with correct wiring)

It’s a level of engineering that not only keeps the wings strong but makes the entire plane future-proof. Because nothing ruins a build faster than realizing you can’t replace a $12 servo without destroying $200 worth of fiberglass and foam.